Generation method

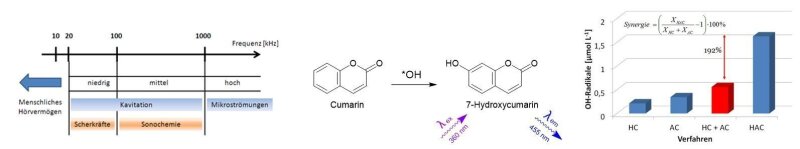

Cavitation methods have many applications in (environmental) process engineering, whereby various processes can be initiated, activated or intensified. In the working area different generation processes (hydrodynamic, acoustic, simultaneous) are investigated and further developed.

Frequenzabhängige Wirkungen des Ultraschalls sowie verschiedene Generierungsmöglichkeiten von Kavitation und ausgebildete Synergien (P. Braeutigam, Handbook of Ultrasonics and Sonochemistry, Springer, (2016))

Image: internCavitation field analysis

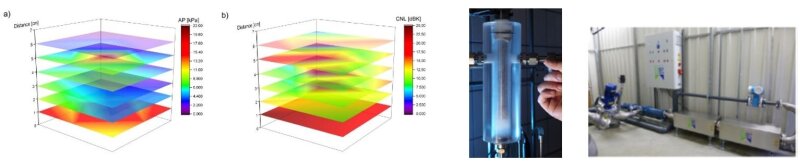

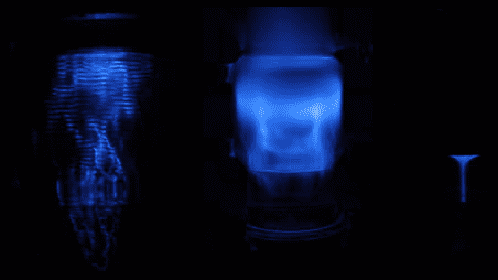

For the further development of cavitation methods or cavitation-assisted methods, cavitation field analysis is carried out as a support. This uses optical or acoustic information and provides an insight into the qualitative and quantitative distribution of cavitation fields in the reactor. Furthermore, methods are used to determine the temporally and spatially resolved bubble fields. With this information bubble field and cavitation field can be correlated with the corresponding result (turnover, mineralization, particle size etc.) and used for reactor design as well as for process engineering design.

Blasenfeldverteilung bei hydrodynamischer Kavitation (links), Sonochemilumineszenz von Luminol zur Visualisierung von Kavitationsfelder in Reaktoren (Mitte) sowie Auswertung über den Kavitationsrauschpegel (P. Finkbeiner at al., Chemical Engineering Journal, 73, 214, (2015))

Image: internReactor development

In the research group, cavitation reactors are designed, built and tested for various fields of application as well as optimised and further developed. This also includes the integration of sensor technology and, if possible, basic control and regulation of the plants (e.g. based on Arduino, Labview or SPS, with partners). Furthermore, industrial plants are also designed and adapted on the basis of laboratory tests together with corresponding companies.

Reaktorchrakterisierung auf Basis von Schalldruck und Kavitationsrauschpegel (links), Entwicklung von Reaktoren und Anlagen, die hydrodynamische und akustische Kavitation nutzen (Mitte) und industrielle Umsetzung einer Anlage zur Desintegration (M. Weiße et al., Ultrasonics Sonchemistry 60, 104801, (2019))

Image: internProcess intensification and Sonochemistry

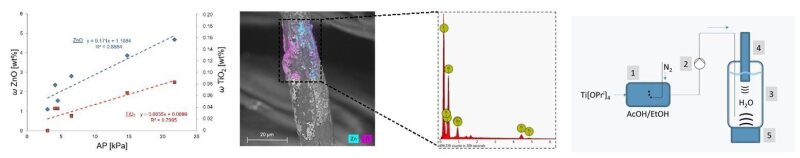

Cavitation phenomena can be used for process intensification and various sonochemical applications due to the temperatures and pressures generated during collapse as well as the shear forces and microjets. In the working group hydrodynamic, acoustic and simultaneous cavitation are applied for intensification of mass transport limited reactions, for the synthesis of (amorphous) (nano-)particles, for the coating of textiles or for the improvement of mass separation processes (e.g. extraction) as well as in the fields of water technology and in the material or energetic use of biomass.

Sonochemical coating: Beladung von TiO2 und ZnO in Abhängigkeit des Schalldruckes (links), REM und EDX einer beschichteten Textilfaser (Mitte) und Fließschema zur sonochemischen Erzeugung von TiO2-Partikeln (M. Weiße et al., Ultrasonics Sonchemistry 60, 104801, (2019))

Image: intern