Bioenergy

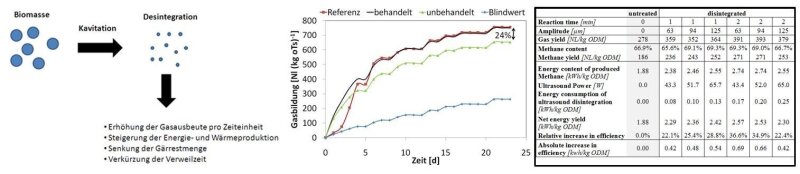

For process intensification of biogas and digester gas production, methods are used which improve the speed-limiting process step of hydrolysis. Cavitation processes can be used for this purpose, as they support the digestion of the biomass and, in addition to increasing the biogas yield, reduce the amount of fermentation residue and lead to significant improvements in the downstream processes. For this reason, pretreatment processes are also regarded as the key to the efficient material and/or energy use of biomass. In the research group, cavitation-based processes for disintegration of biomass or sewage sludge are investigated and further developed. Here, the focus is on energetic optimisation and reactor design.

Prinzip des Einsatzes der Ultraschalldesintegration zur Steigerung der Biogas- bzw. Faulgasausbeute (links), Effekt auf das Gasbildung (Mitte) und energetischer Vergleich (rechts) (P. Braeutigam et al., Biomass and Bioenergy, 63, 109, (2014))

Image: internBiofuels

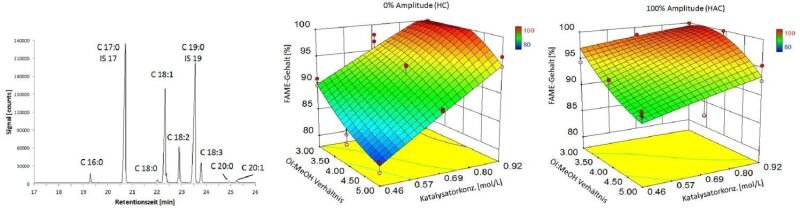

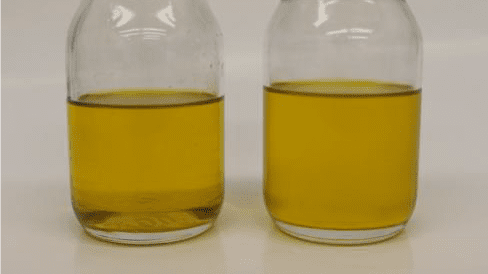

Fuels made from renewable raw materials contribute to ensuring mobility, combined with various inherent advantages and disadvantages. In the work area, new concepts for the production of biodiesel are being developed that use alternative energy inputs and oils that are not used as food. Furthermore, the corresponding methods for the characterization of biodiesel are applied.

Charakterisierung von Biodiesel anhand des Fettsäuremethylesterspektrums (links) sowie Synthese und Optimierung der Verfahren mit Hilfe statistischer Methoden des Design of experiments (rechts)

Image: internBiopolymere

The research group also develops processes for the material and energy recovery of biodegradable plastics. Conventionally, these are composted or burned, whereby the chemically bound energy is lost unused and the ecological or economic benefit is greatly reduced. Furthermore, biodegradable plastics cause problems in large-scale composting plants during operation. Within the scope of our research activities, pre-treatment processes for the improved energetic utilisation of these or processes for solution or repolymerisation in the sense of material recycling have therefore been developed. In addition to polylactic acid and polyhydroxyalkanoates, various starch and cellulose derivatives are used for this purpose.

Lösungsgrad verschiedener bioabbaubarer Kunststoffe (links), Lösung von bioabbaubaren Kunststoffe am Beispiel von PLA sowie Rückstand und Lösung (Mitte) und Repolymerisation von PLA aus der Lösung (rechts)

Image: internControl / regulation

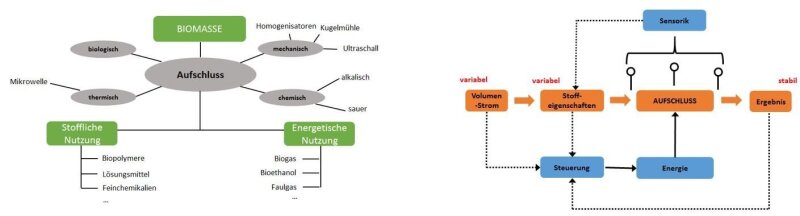

Within the scope of the research activity it is tried to make digestion processes for the material or energetic biomass use controllable in terms of process engineering and to use the instrumentation already existing on the corresponding plants (e.g. biogas plants, digestion towers) and to be able to react adaptively and in real time to fluctuating educt qualities.

Prinzipielle Möglichkeiten der Nutzung und Vorbehandlung von Biomasse (links) sowie Grundprinzip des Steuer/Regel-Systems für Aufschlussprozesse (rechts)

Image: internTextile functionalization with renewable raw materials

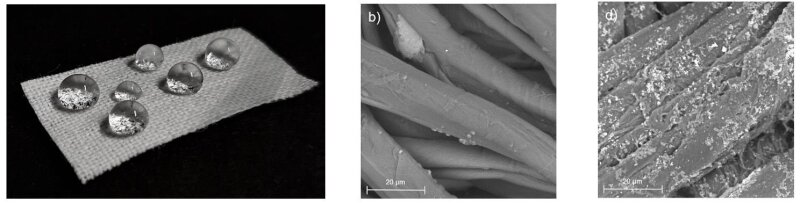

The demand for functional and sustainable textiles with improved properties, such as antibacterial activity, self-cleaning properties, flame or UV protection, is constantly increasing. Within the scope of the research activities, cavitation-supported methods for the application of nanoparticles to textile fibres are investigated. In addition to frequency and amplitude of the ultrasound (sound field, cavitation noise level, reactor design), the precursor and the textile structure play a decisive role - especially with regard to activity and washing stability. In addition to the sonochemical coating, functionalizations are applied to the textile fibers, for example to generate hydrophobic surface properties. Conventionally, this is achieved using fluorinated silanes. In contrast, the research group uses functionalization reagents that are fluorine-free, less expensive, more stable and environmentally friendly compared to the state of the art. These are also biodegradable and can also be obtained from renewable resources.

Modifizierte Baumwollprobe mit wasserabweisender Schicht (links) sowie REM-Aufnahmen den unbeschichteten und beschichteten Baumwollfasern (rechts) (M. Weiße et al., Ultrasonics Sonchemistry 60, 104801, (2019))

Image: internBiogenic residues

The material and energetic use of biogenic residues is part of the working spectrum of the research group. For example, restaurant fat is used as an educt for the synthesis of biodiesel and corresponding reactors and processes are developed. Furthermore, investigations and a supporting process development for the material use of vinasse, the by-product (stillage) of the bioethanol process, are being carried out. For example, a production process has been developed that uses both the organic and inorganic components of vinasse to produce high-quality fish feed or high-quality oils. In addition to the "zero-waste concept" (e.g. treatment of process water containing phenol), the focus was also on the economically attractive use of vinasse.